Whitewater legume demonstration site establishment – a tale of the drone and the tractor

The site that needed legumes

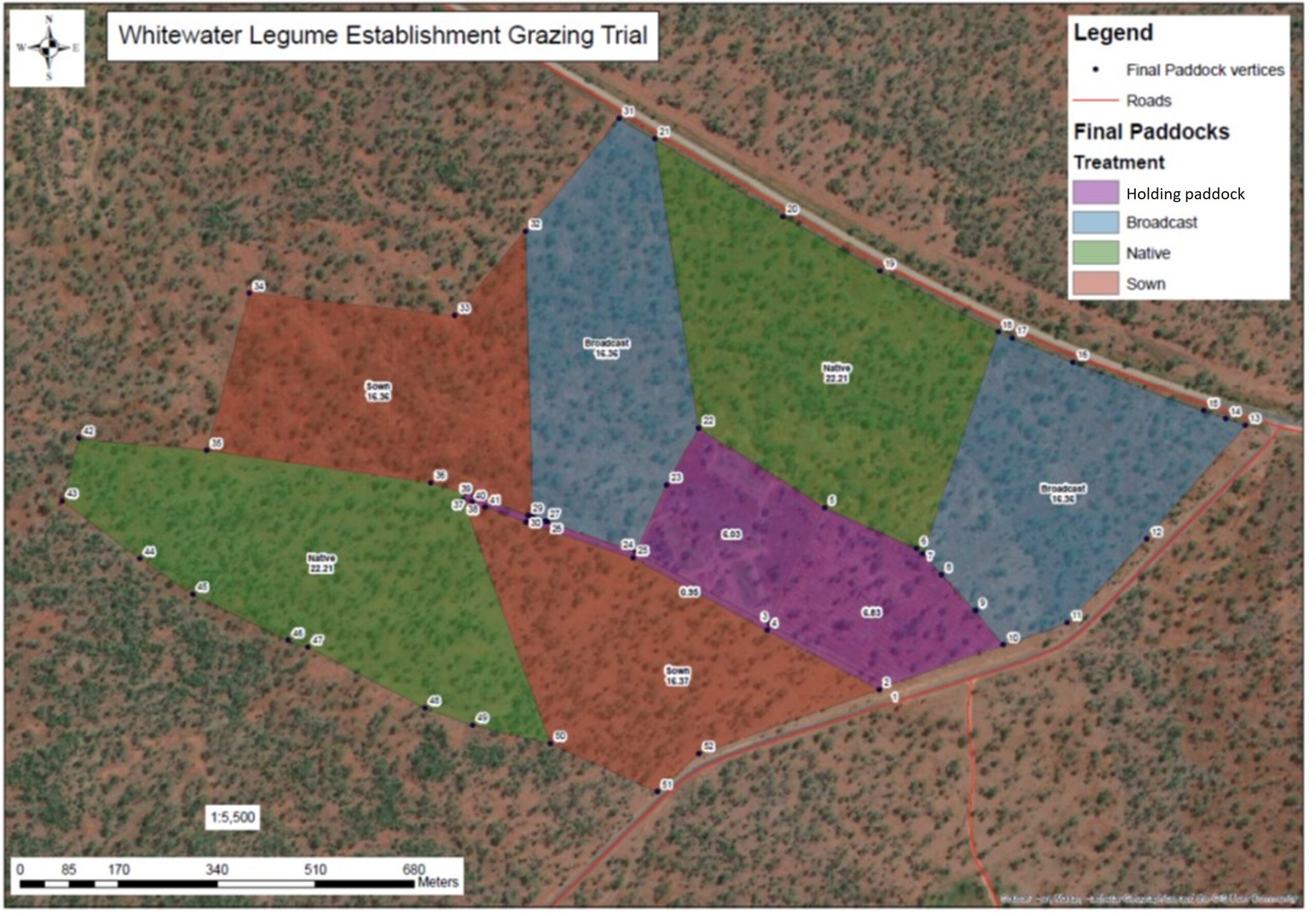

The Whitewater legume demonstration site is in the McBride basalt province of north Queensland. The area was surveyed and found to have very low levels of stylo, with the pasture dominated by Indian couch, grader grass and black speargrass. The demonstration has 6 paddocks to compare 2 legume establishment methods with a control. The three treatments are:

- Native (control)

- Broadcast (fire-drone-broadcast) establishment

- Sown (tractor-herbicide-strips) establishment

The treatments were mapped and fenced during 2023-24, with two paddocks for each treatment. The aim of the demonstration is to determine which method is the most successful for establishment and cattle production. More detailed information on this demonstration can be found here.

The drone – ‘broadcast’ treatment

Monday 9 December 2024 dawned fine and clear at Whitewater Station. An early start had DPI’s Kendrick Cox and Craig Lemin meeting on-site with the drone operator at 7 am. Two 17 ha paddocks – part of a Queensland Pasture Resilience Program legume demonstration site at Whitewater, had been burnt two days before. The aim was to broadcast stylo seed using the drone before the usual south-easterly wind got up. Seed needed to be broadcast into the ash bed before the next storm rain, when it could germinate and have the best chance of competing against existing grasses that would quickly regrow.

Two 51kg batches of tested stylo seed were pre-mixed ready for broadcasting – one batch for each paddock and each comprising equal weights of Seca, Verano and Primar stylo. Broadcasting began once the paddock boundary was defined and a flight plan was made. The drone flew at about 25 metres – just above the top of the tallest trees. The first paddock took about 90 minutes to seed. Initially, seed was going on too heavily. The hopper opening was progressively reduced to make sure the seed would last the whole paddock.

The second paddock took less than an hour since the broadcast rate was worked out. The 51kg batch was spread in four loads of 12-13kg each compared to the 50kg payload. The wind stayed down and all was finished by midday.

Within a week, storms and consistent rain arrived at Whitewater – over 300 mm was received making it one of the wettest Decembers on record. There was no excuse for the stylo seed! The rain eased and conditions dried in late December, it was now the turn of the tractor.

The tractor – ‘sown’ treatment

Just before Christmas, the owner, Tom Saunders, used a tractor and chisel plough to cultivate in the two 17ha strip paddocks. Driving at 10-15m between runs, Tom weaved his way through the trees and rock outcrops to cultivate a network of strips into which stylo would be sown. Sometimes the strips wandered apart, sometimes they merged then separated again, sometimes they diverted around denser areas of rock; all were ringed-in by the boundary fence. The end result was about 11 km of strips in one paddock and 12 km in the other (2.4 m wide). These strips were re-worked at the start of January with each working taking a day on the tractor.

The wet season break continued into the New Year, but with more rain forecast the North Queensland Pasture Resilience Program team swung into action during the second week of January. Two more 51 kg batches of stylo seed, the same as used in the broadcast paddocks was stored ready for sowing into the strips. Beginning 9 January, the strips were sprayed with glyphosate applied at 1.2 L/ha using a small boom spray. The full width of the cultivated strip was sprayed, with some overspray into the adjacent grass on each side. Preparations were made for sowing the following week.

On 14 January, the site was inspected – the result of the previous weeks spraying was disappointing, possibly due to the quality of the water used for mixing. The decision was made to re-spray most of the strips, requiring another days work. The following day the site was ready – a buggy with seed spreader attached was used to spread the stylo seed over the cultivated strips. At Tom’s suggestion, Butterfly Pea seed was also included and was spread with the stylo (also at 1kg/ha). The spreader settings were fine-tuned to make sure the seed could be spread over all the strips in each paddock.

Closely following the buggy, a Cambridge roller (flange or ring roller) was towed over the sowed strips to firm the seedbed. It was not ideal in the rock, but mostly did a good job. On completing the last run of the day – the threatening skies opened and about 40 mm of rain fell in 30 minutes forcing a hasty retreat.

Comparing the two sowing methods

The two drone-broadcast paddocks had taken about a day to complete – half a day for burning and half a day for broadcasting – whereas the tractor-sown strip paddocks added up to about five days. But who won – the drone or the tractor? Or as the fable goes – the hare or the tortoise?

There was no shortage of rainfall for either method, good rain was received consistently for several weeks after each sowing. Establishment surveys were done in the drone-broadcast and tractor-strip treatments on 1 April and 8 April respectively (16 and 12 weeks after sowing in each case).

Walking around the site, the stylos in the tractor-sown strip were obvious. In April, most strips were thickly populated with stylo about 200-300 mm high. The Butterfly Pea was also doing well, but there was not much else in the form of competitive grasses. In the drone-broadcast paddocks it was a different story. Looking carefully, you could find stylo seedlings beneath the regrowth of grader grass, black speargrass and Indian couch, but they were generally only 50-100 mm high. Nonetheless, they were judged to be adequately established to survive the dry-season. Aside from just looking – what did the numbers say?

To measure the success of each establishment method, the maximum population density – based on every viable seed germinating (calculated from the germination tests and sowing rate), was compared to the actual establishment density in each paddock, measured by quadrat surveys. Note that on a whole paddock basis, the sowing rate for strip paddocks was the same as for the broadcast paddocks, but because the seed was concentrated into the strips, the sowing rate in-the-strips was much higher.

Table 1 shows the maximum overall plant density possible in paddocks assuming seed was spread evenly across the whole paddock and all the viable seeds germinated and survived. Since the overall sowing rate was the same for all paddocks the maximum overall plant density is also the same for all paddocks, that is 23 stylo plants/m2 (adding Seca, Verano and Primar together); and 1.4 Butterfly Pea plants/m2 (which was only sown in the tractor-strip paddocks).

Table 1. Maximum overall plant density possible in each paddock, based on germination tests.

| Sowing rate (kg/ha) | Seed quantity (number/g) | Germination (%) | Maximum field density (plants/m2) | |||

|---|---|---|---|---|---|---|

| Stylo | Seca | 1 | 402 | 13 | 5.2 | |

| Verano | 1 | 264 | 30 | 7.9 | ||

| Primar | 1 | 408 | 25 | 10.2 | ||

| Butterfly Pea | Milgarra | 1 | 21 | 69 | 1.4 |

In the Table 2, the average measured cover and the plant density are shown for each establishment method. Two plant densities are given for the tractor-sown strip paddocks. The first is the result measured within the strips whereas the second is the result for the whole paddock, that is considering the proportion of strip area relative to the paddock area. This gives a direct comparison with the broadcast paddocks.

Table 2. Average cover and plant density for each establishment method.

| Broadcast | Sown strips | |||||||

|---|---|---|---|---|---|---|---|---|

| All stylos | All stylos | Butterfly Pea | ||||||

| Cover (%) | Plant density (no./m2) | Cover (%) | Plant density in strip (no./m2) | Plant density overall (no./m2) | Cover (%) | Plant density in strip (no./m2) | Plant density overall (no./m2) | |

| Average | 0.75 | 1.6 | 15.4 | 45.0 | 5.6 | 5.3 | 3.3 | 0.4 |

For the drone-broadcast paddocks the average stylo plant density was 1.6/m2 – which was 7% of the maximum possible – in other words more than 90% of seed didn’t establish. For the tractor-sown strip paddocks, the average stylo plant density overall was 5.6/m2 or 24% of the maximum possible; with additional Butterfly Pea plant density at 0.4/m2, which was 29% of the maximum possible.

Just considering the stylos, the overall plant density achieved in the tractor-sown strip paddocks was 3.5 times higher than for the drone-broadcast paddocks (56,000 plants/ha versus 16,000 plants/ha). The plants in the strips were also more advanced than those in the broadcast paddocks which is reflected in the higher cover ratings in the strip paddocks.

A knockout result?

The tractor seems to have had a clear win! That’s not to say the drone doesn’t have its merits – there are many possibilities for using this technology to broadcast seed. The reality is, this demonstration wasn’t really comparing a drone to a tractor, it was comparing seed bed preparation and competition control. At Whitewater with fertile soils and vigorous grass competition, cultivating a seed bed and using herbicide to control grass competition, shows a clear advantage for legume establishment compared to burning and broadcasting seed into an ash bed. The proof will be in the grazing trials to come. Whitewater heifers have now been weighed, with three even groups allocated for use at the site. Grazing will start in mid-June. Look out for future updates on results and progress at the site.

This work continues under the Queensland Pasture Resilience Program which is a partnership between the Department of Primary Industries, Meat & Livestock Australia and the Australian Government through the MLA Donor Company.